|

||

| > Reader's Photo OX5 by Lockheed Martin |

||

| • ADVERTISE WITH US | ||

| • WHO IS MOAB JEEPER? | ||

Home > Jeep Articles > Technical & Installation - Tools > Threaded Insert Riveter |

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

|

Threaded Insert RiveterArticle written by Moab ManDate Added: 08/24/2008 There are not a lot of tools we don't have here at MOABJEEPER Magazine. So when we got the chance to purchase a new tool, we couldn?t wait to tell you about it. |

|

Bolting things to sheet metal can present a challenge if the back side of the metal is not accessible. If you can?t reach both sides of the sheet metal due to its location or if it?s a sealed box, you can?t use a standard nut and bolt. Unfortunately, you can?t just tap sheet metal and thread a bolt in there because it isn?t thick enough, and the threads will just strip. What you need is a threaded insert that can be placed in the sheet metal plate from one side. Fortunately, there is a tool for doing just that. Bolting things to sheet metal can present a challenge if the back side of the metal is not accessible. If you can?t reach both sides of the sheet metal due to its location or if it?s a sealed box, you can?t use a standard nut and bolt. Unfortunately, you can?t just tap sheet metal and thread a bolt in there because it isn?t thick enough, and the threads will just strip. What you need is a threaded insert that can be placed in the sheet metal plate from one side. Fortunately, there is a tool for doing just that.

|

||||||||||

|

Installation | |||||||||||

|

1. Threadserts are a threaded insert you put in a piece of sheet metal. The tool looks and works like a pop rivet gun. Depending on what size threadsert you need, the riveter gun will have to be assembled. Here are all the parts needed. From left to right:

|

||||||||||

|

2. This is what the tool looks like fully assembled. |

||||||||||

|

3. To demonstrate how this tool works, we will use this washer to serve as the sheet metal we need to bolt a "widget" to. The center hole in the washer is the hole you would have drilled in the sheet metal with the appropriate sized drill bit.

Minimum thickness of the sheet metal for this tool is 1/32".

|

||||||||||

|

4. Here we are ready to install the threadsert. |

||||||||||

|

5. We have inserted the threadsert through the sheet metal (washer for our demonstration). |

||||||||||

|

6. Holding the threadsert flush against the sheet metal, compress the riveter gun.

Notice the bulging threadsert.

|

||||||||||

|

7. Continued compression of the threadsert. |

||||||||||

|

8. Almost complete. |

||||||||||

|

9. Threadsert is now fully installed in our "sheet metal." |

||||||||||

|

10. The face of the threadsert is scalloped so that it grips the sheet metal and doesn't spin. Of course, the threadsert is aluminum so don't over-torque the bolts in them. If you need greater strength, and to be able to apply a fair amount of torque to your installation bolts, threadserts can also be purchased in steel. |

||||||||||

|

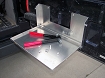

Final ThoughtsThis tool will have all kinds of uses. We wished we had come upon it sooner. To purchase this tool from Harbor Freight: ITEM 1210-6VGAIn case you?re wondering what the occasion was for picking up our sweet new tool, check out the picture for a sneak peek of next weeks article. |

||||||||||

Purchase / Vendor Info

|

| Vendor Name: | Harbor Freight |

| Address: | 3491 Mission Oaks Blvd Camarillo, CA 93011 |

| Phone: | 800-423-2567 |

| E-Mail Address: | |

| Website: | http://www.harborfreight.com/ |

Our

Thank You's!

Our

Thank You's!

Thank you for reading MOABJEEPER Magazine.